Engine Mounts

results

Featured Brands

No photo

40661

Engine Mounting

Febi

€1.50

No photo

01516

Bump Stop

Febi

€1.71

No photo

17877

Engine Mounting

Febi

€2.01

No photo

01930

Bump Stop

Febi

€2.17

No photo

21652153

Rubber Buffer engine mounting

Corteco

€2.33

No photo

22936

Bump Stop

Febi

€2.34

No photo

01929

Bump Stop

Febi

€2.42

No photo

09400

Engine Mounting

Febi

€2.43

No photo

80000214

Rubber Buffer engine mounting

Corteco

€2.71

No photo

80000278

Rubber Buffer engine mounting

Corteco

€2.74

No photo

80000258

Rubber Buffer engine mounting

Corteco

€2.83

No photo

23584

Bump Stop

Febi

€3.12

No photo

23537

Bump Stop

Febi

€3.14

No photo

23440

Bump Stop

Febi

€3.15

No photo

07180

Axle Beam Mounting / Engine Subframe Mou

Febi

€3.40

No photo

37527

Bump Stop

Febi

€3.45

No photo

07182

Axle Beam Mounting / Engine Subframe Mou

Febi

€3.59

No photo

23408

Bump Stop

Febi

€3.88

No photo

01518

Axle Beam Mounting / Engine Subframe Mou

Febi

€4.06

No photo

07181

Axle Beam Mounting / Engine Subframe Mou

Febi

€4.32

Buy car parts from the most popular car brands

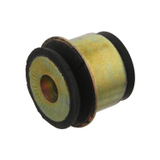

Engine Mounts

Engine mounts are critical components securing the engine and transmission assembly to the vehicle chassis. They isolate vibration and dampen noise generated by engine operation, preventing transfer to the passenger compartment. These mounts utilize varying durometer rubber or fluid-filled designs to manage dynamic loads and frequency. Construction typically includes a steel housing bonded to an elastomeric core, with variations for different engine weights and vehicle applications. Hydraulic or active engine mounts utilize fluid control to further minimize vibration under specific operating conditions. Failure manifests as increased NVH, driveline clunk, or engine movement.

Have a question?

Send us a message on WhatsApp